Common Mistakes to Avoid with DTF

Direct-to-Film (DTF) transfers are transforming custom apparel with vibrant, long-lasting prints and unmatched versatility. However, achieving professional results requires precision and the right techniques. Avoiding these common mistakes will elevate your DTF heat transfers, ensuring consistent, high-quality outcomes.

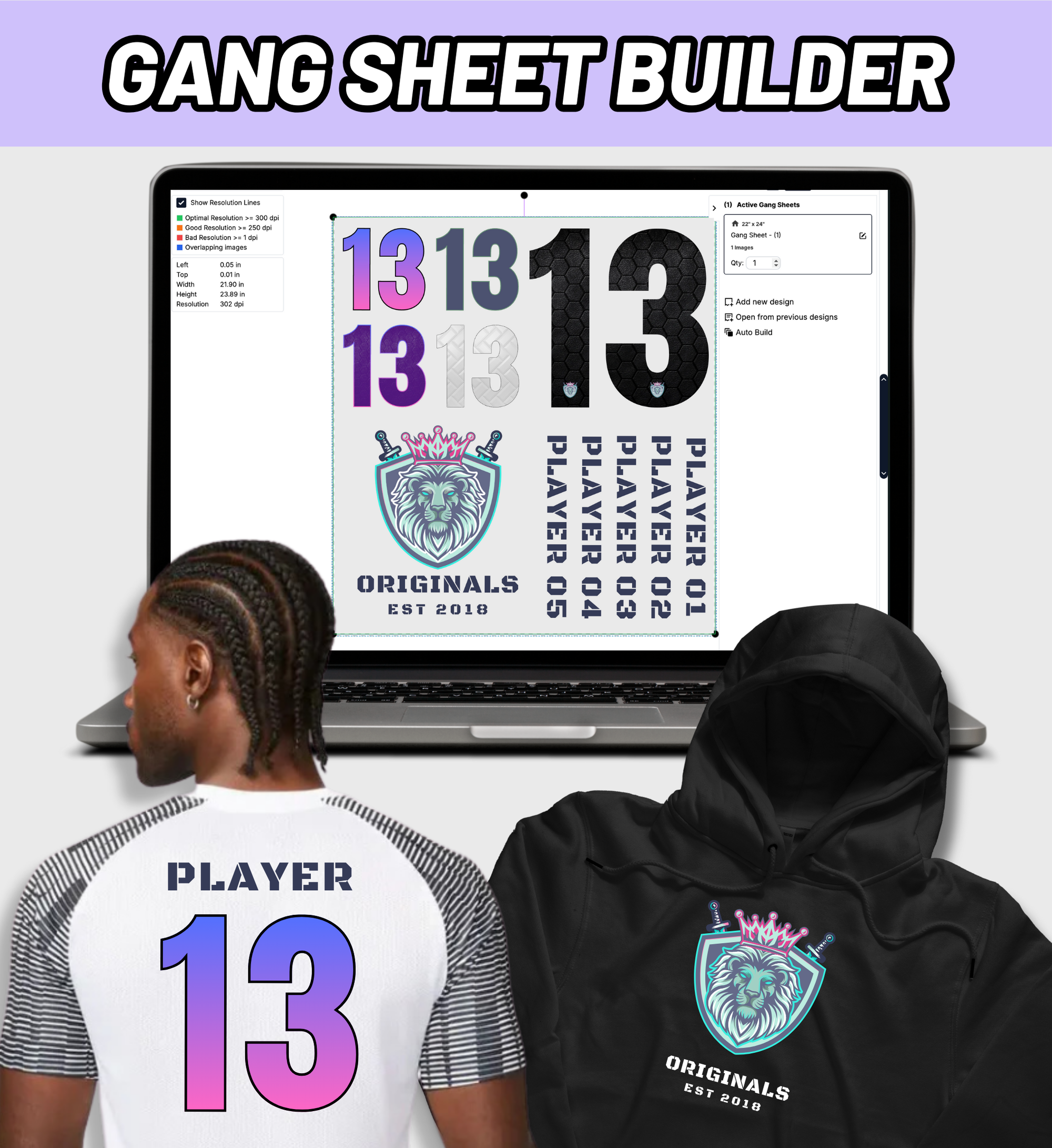

1. Skipping Proper Artwork Preparation

Properly prepared artwork is essential for achieving crisp, vibrant prints. Missteps in file preparation can lead to dull colors or blurry designs. Here’s how to ensure your artwork is ready for DTF transfers:

- Use high-resolution files: 300 DPI is the standard for sharp, detailed prints. Avoid using low-resolution images that appear pixelated when transferred.

- No need to convert RGB to CMYK: A common misconception is that you must convert RGB files to CMYK in your design software before sending them for printing. At 613DTF, our advanced RIP (Raster Image Processor) software handles the conversion from RGB to CMYK far better than most design programs, ensuring your prints are as vibrant and accurate as possible.

- Check for transparency and hidden layers: Clean up your files by removing unnecessary layers or elements that could interfere with the final transfer.

By preparing your artwork correctly, you'll set a strong foundation for flawless DTF heat transfers.

2. Incorrect Heat Press Settings

Your heat press settings are critical for ensuring a high-quality result with your DTF transfers. At 613DTF, we recommend the following settings, tested and proven to work perfectly with our transfers:

- Temperature: Set your heat press to 300°F. This precise temperature activates the adhesive and ensures a strong bond without risking damage to the transfer or garment.

- Pressure: Use medium to heavy pressure. This helps evenly apply the transfer to the fabric, ensuring no peeling or missed areas. A properly calibrated press makes a noticeable difference.

- Time: Press for 7 seconds. Our transfers are designed to provide fast, efficient application.

- Peel immediately (hot peel).

3. Improper Storage of Transfers

DTF transfers are sensitive to environmental conditions, and improper storage can ruin their performance. To maintain the quality of your transfers:

- Keep transfers flat: Avoid rolling or folding your transfers to prevent creases that can affect the print. Use flat storage solutions for best results.

- Store in a cool, dry place: Transfers should be kept away from humidity, direct sunlight, and heat sources. Aim for temperatures below 75°F and low humidity.

- Seal for long-term storage: Protect transfers from moisture by using resealable bags or moisture-proof containers.

Proper storage ensures your transfers are ready to deliver vibrant results whenever you need them.

4. Skipping the Pre-Press and Lint Removal Steps

Prepping your garment is a step that's often overlooked but is critical for achieving smooth, professional-looking DTF transfers.

- Pre-press your garment: Before applying the transfer, press the garment for 5–7 seconds to remove moisture and wrinkles. This creates a flat, clean surface for optimal adhesion.

- Use a lint roller: Roll over the print area to remove fibers, dust, or debris. These can interfere with adhesion and result in uneven prints.

- Clean your heat press platen: A dirty press surface can transfer contaminants to your garment, ruining your work.

These small steps ensure a polished, professional finish every time.

5. Ignoring Supplier Guidelines

Not all DTF transfers are created equal. Each supplier's product has unique requirements to deliver the best results. To get the most from your 613DTF transfers:

- Follow our detailed instructions: Our guidelines include recommended temperature, pressure, and timing settings tailored to our transfers.

- Reach out for support: If you're unsure about a step or experiencing issues, contact our team. We're here to help you get the most out of your transfers.

6. Using Incompatible Fabrics

Choosing the right fabric is just as important as perfecting your technique. Some materials aren't suited for DTF transfers and can cause adhesion or design issues.

- Compatible fabrics: DTF transfers work best on cotton, polyester, cotton/poly blends, and certain synthetics. These fabrics provide a solid bond for long-lasting results.

- Fabrics to avoid: Heat-sensitive materials like nylon, heavily waterproof-coated fabrics, or highly textured fabrics such as waffle knits or thick ribbing. These materials make it difficult for the adhesive to bond evenly, leading to poor results.

- Special note on dye-sublimated polyester: This fabric often causes dye migration, where the underlying dye seeps into your design, distorting its appearance. For such challenging materials, we recommend our Hybrid Transfers, engineered to resist dye migration and deliver vibrant, clean results.

Pro Tips for Success

- Test Before You Press: Always test a sample transfer on a similar garment to confirm your settings and ensure a flawless finish.

- Invest in Reliable Equipment: A high-quality heat press with consistent temperature and pressure ensures professional results.

- Choose a Trusted Supplier: 613DTF.com provides premium DTF transfers backed by expert support to help you succeed.

By following these tips and avoiding common mistakes, you'll achieve stunning, professional-grade results with your DTF heat transfers every time. Ready to take your custom apparel business to the next level? Shop our DTF Transfers today and experience the 613DTF difference!